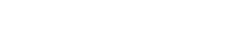

Jacketing Isolpak PVC

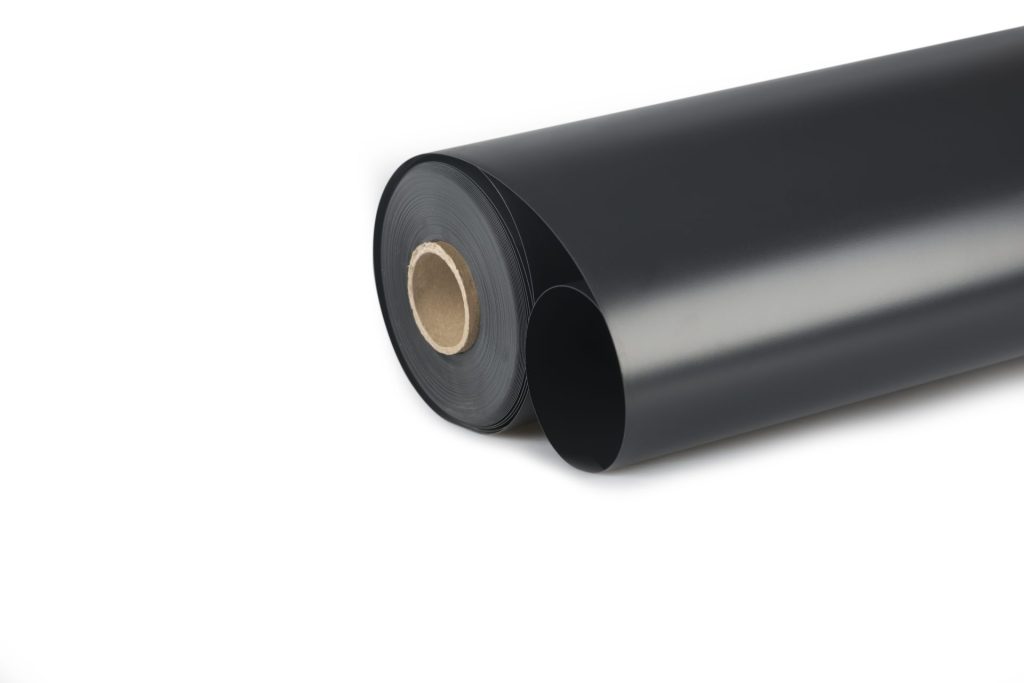

Isolpak PVC is a special rigid PVC film for jacketing of insulated pipes: thank s to the inherent curl, it is the ideal material for quick and easy covering. A dry, clean fitting is guaranteed.

It has a light grey smooth surface, which assures a long-lasting elegant appearance.

Isolpak PVC benefits

Unbeatable advantages, low material cost, ease of Material preparation and fast installation

Isolpak PVC is an easily usable material for rapid covering and it is extremely resistant to damaging environmental effects.

- Isolpak ALU is self-extinguishing

- The foil has considerable resistance to acids, alkalis, salts, oil, petrol, alipathic hydrocarbons and corrosive atmospheres

- It cannot corrode and is virtually impermeable to water vapour

- The material is unaffected by fresh and salt water and imprevious to gases, grease and oil

- Physiologically harmless, It requires no care or maintenance due to very good antistatic characteristics

- Isolpak PVC is very light: One square metre, 0.350 mm thick, weighs only about 500 g

- The installation is easy and needs no expensive tools

- The curling effect completes a perfect, clean and fast installation

- considerable resistance to temperature changes and is stable from -20°C up to +65°C in indoor use

Technical Data Isolpak PVC

| Property | Norm | unit | Value |

| Thickness | my | 280, 300, 350 | |

| Breaking load | DIN 53 455 | N/mm² | 30 – 35 long. |

| N/mm² | 25 – 30 horiz. | ||

| Tensile strength | DIN 53 455 | N/mm² | 40 – 45 long. |

| N/mm² | 34 – 40 horiz. | ||

| Elongation at break | % | 150 – 200 long. | |

| % | 100 – 150 horiz. | ||

| Withdrawal value | % | 2,5 – 3 long. | |

| % | 0,0 – 0,5 horiz. | ||

| Thermostability | °C | -20 to +60 | |

| Softening point (VICAT) | DIN 53 460 | °C | 74 (+/-1) |

| Density | g/ccm | 1,38 (+/-0,01) | |

| Recoil/Curl effect | mm | 85 (+/-10%) | |

| Reaction to fire | DIN 4102 | B2 [CH: 5.2] [ITA: Classe 1] | |

| Standard size | mm x m | 1000 x 25 | |

| Resistance to humidity | DIN 52615 | µ | Ca. 60000 |