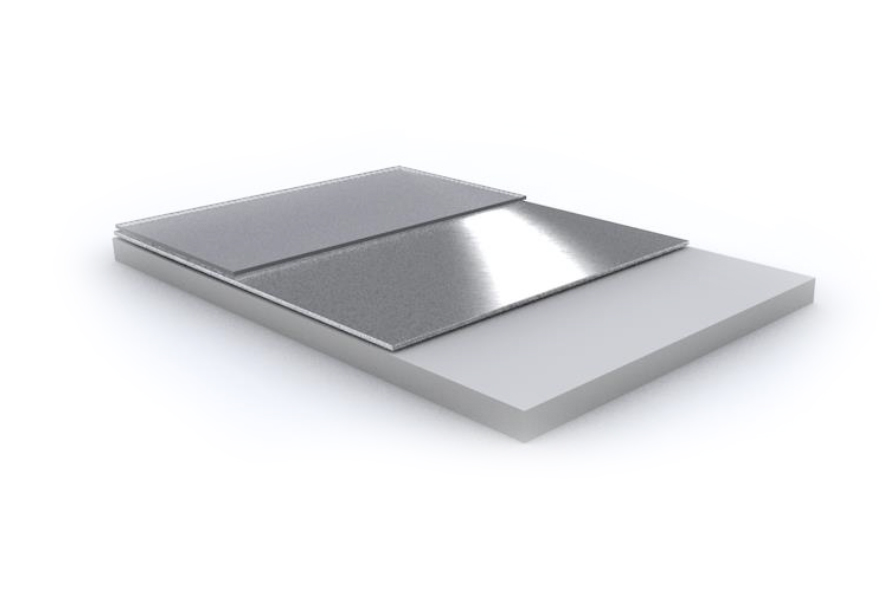

Isolpak ALU INDOOR

Isolpak Alu Indoor is an innovative insulation jacketing for indoor use: thanks to its multilayer construction it provides unprecedented features in technology and efficiency.

Isolpak alu Indoor differs particularly by its metallic appearance, especially thanks to the intermediate layer of pure aluminum. A layer of an extremely durable BOPET film ensures a highly tear resistance, also towards damaging environmental effects. Ideal for interior facing of hot and cold insulation, as it is partially flame retardant.

Product introduction

Play VideoMounting options

Play VideoRendering

Isolpak CLAD benefits

Unbeatable advantages, low material cost, ease of Material preparation and fast installation

Isolpak Alu Indoor combines excellent vapor barrier with water tightness. It is an easily usable material for rapid covering and it is extremely resistant to damaging environmental effects.

- Isolpak ALU is a sign for the environment, hygiene and safety

- The foil does not use any heavy metals

- It is free of ozone-depleting CFC and HCFC compounds

- The material is almost [<0.5%] completely free of plasticizers

- Free of silicones

- Isolpak ALU can be used without any restriction in food processing plants

- The standard rolls of 1m x 25m only weigh about 12,5 KG

- The installation is easy and needs no expensive tools

- The curling effect completes a perfect, clean and fast installation

- No special care or maintenance is required due to antistatic components

- Partially acid-, alkali-, salt solution-, fat-, oil-, bacterium- and fungus-resitance

PVC (FR) Design: The key success factors of ISOLPAK PVC

Pure aluminum: technical advantages of aluminum

Transparent BOPET layer: protection from damaging external environmental effects

Result:

- economic alternative to current real metal jacketing systems

- ensures high chemical resistance combined with low thermal conductivity

Technical Data Isolpak ALU INDOOR

|

Property |

Norm |

unit |

Value |

|

Total weight |

g/m² |

330 |

|

|

Thickness appr. |

mm |

0,230 |

|

|

Thickness tolerance |

mm | ± 0,05 | |

|

Width |

mm |

1000 / 1065 |

|

|

Width tolerance |

mm |

± 2 |

|

|

Tensile strength |

EN ISO 527-3 |

N/15 mm |

min. 200 |

|

Elongation at break |

EN ISO 527-3 |

% |

48 |

|

Tear strength |

EN ISO 527-3 |

N |

70 |

|

Puncture ∅ 3,0mm |

prEN 14 477 |

N |

23 |

|

LOI [Limited oxygen index] |

% O² |

35,5 |

|

|

Sd-Value |

1500 |

||

|

Temperature resist. |

°C |

-25 to +65 |